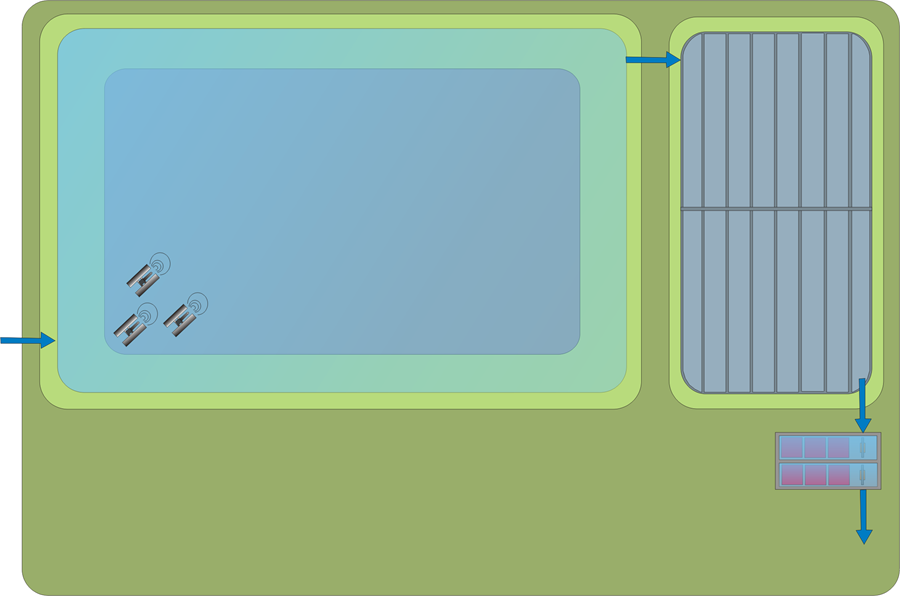

The first stage of the LemTec™ Partial Mix Facultative Treatment Process (LPMFTP) is primarily an aerobic process. Its most unique feature is that it relies on a traditional facultative treatment process that is augmented by the LemTec™ Partial Mix Aeration Process which enhances BOD removal, reduces algae growth and also aides in sludge digestion.

The Aeration Process design may consist of one or several partial mix aeration cells. By creating partial mix aeration cells within the facultative environment, Lemna can expand upon the facultative process and improve the lagoon’s capabilities, providing consistent, reliable BOD removal while setting the stage for the remaining treatment objectives. Sophisticated process modeling ensures that the partial mix aeration process is maximized, designed to perform consistently and reliably even during high flow conditions or variable influent loading. The other primary function of the partial mix aeration cells is to begin the process of sludge digestion and stabilization.

By covering the settling zone of the LPMFTP with the LemTec™ Modular Insulated Cover System, the covered lagoon system eliminates algae and aquatic growth within the lagoon. Algae and aquatic growth contribute to elevated TSS levels, negatively impact BOD removal and can be the cause of nuisance odors.

After the aerobic process stage of the LemTec™ Partial Mix Facultative Treatment Process (LPMFTP), the next primary step is for sludge reduction and solids management including storage, separation and digestion.

The first consideration is to provide an environment conducive for solids settling. The use of the LemTec™ Modular Insulated Cover System enhances the settling process by eliminating wind and wave action on the lagoon surface. Our cover system also eliminates the stratification of temperatures and prevents pond “turn over” during changes in the season. In addition, our cover system eradicates algae or aquatic growth within the lagoon and the potential for nuisance odors.

To achieve proper sludge digestion and benthal decay, LET provides a unique aeration process within the settling zone. Doing so enhances the digestion process, minimizes the amount of sludge collected and eliminates the risk of benthal rebound. Through this unique settling design, LET can ensure the settling zone will be sized adequately to provide many years of maintenance-free service as it relates to sludge handling.

Depending on our customers’ individual, final treatment objectives, LET is able to include additional treatment steps immediately following the custom-designed LemTec™ Partial Mix Facultative Treatment Process (LPMFTP) settling zone.

The need to reduce ammonia, for instance, is quite common. The use of the Lemna Polishing Reactor™ (LPR) immediately downstream of the settling zone is used to achieve ammonia limits down to less than 1 mg/l. The LPR is a submerged, fixed film, attached-growth process that creates an environment conducive to the growth of nitrifying bacteria necessary for ammonia removal and BOD polishing. Further nutrient removal, beyond ammonia may be required.

The LemTec™ Phosphorus Removal System (LPRS) can be designed into the upgrade of facultative lagoons by including the system into our process design prior to the wastewater reaching the final LPR step. The LPRS is comprised of a chemical dosing system, low horsepower pumps and mixers. The phosphorus removal process precipitates phosphorus and allows contaminants to be dissolved or suspended to settle out as floc particles, achieving effluent of 1 total phosphorus for our clients.

Other steps can be added to adapt the LPMFTP and enhance its capabilities to accomplish virtually any treatment objective including Total Nitrogen (TN) removal, additional solids capture, and more. With each customized LPMFTP design, we are able to successfully deliver wastewater treatment solutions that meet every challenge from influent to effluent.

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA