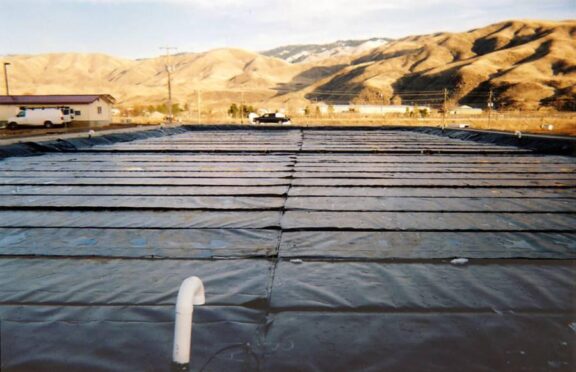

Total suspended solids (TSS) removal is critical for meeting effluent limits for both water and wastewater treatment. The LemTec™ modular cover provides the TSS removal solution for the treatment process. Installing a LemTec™ modular cover over the settling cell of the process creates a clarifier without the moving parts. The innovative cover prevents algae growth as it shields the water from the sun. Additionally, the cover prevents wind action on the water’s surface, creating a quiescent zone for solids to settle. The insulating cover minimizes temperature fluctuations, thereby reducing the undesirable mixing caused by thermal currents. The resulting anaerobic environment digests biosolids significantly over time, reducing the need for sludge disposal to once every five to seven years.

Turbulent mixing throughout the lagoon prevents the thermal stratification that leads to short circuiting and raw wastewater solids in the effluent, as indicated when TSS levels are too high. LET’s Aeration Technologies ensure that proper mixing delivers guaranteed results that meet effluent limits. Proper mixing and aeration prevents algae overgrowth, which can cause high TSS levels, and also keeps solids in suspension. Keeping solids in suspension and in contact with dissolved oxygen allows for digestion and maintains the system’s optimal performance, rather than the solids being digested and settling as sludge, causing additional issues that hinder the wastewater treatment process.

Advanced TSS removal is accomplished in the LemTec process by a continuous backwash up-flow sand filter. The deep bed up-flow approach allows the filter to operate continuously, as backwashing of the media is an integral part of the filtering process. In addition, the continuous backwash sand filter is easy to operate and allows for mechanical, chemical and biological filtration processes. Raw water enters near the bottom of the tank by means of a stainless steel water distributor. Suspended solids are filtered out as the raw water flows up through the media bed. As the filtrate reaches the top of the filter, it passes over the effluent weir and is discharged. A portion of the filtrate is diverted through the sand washer and used for cleaning and transferring the waste solids.

Expertise as a leader in this industry for 30+ years, an arsenal of cutting-edge technologies and a groundbreaking approach set LET apart by delivering optimized solutions for wastewater applications including TSS Removal to meet clients’ objectives efficiently and cost-effectively. We maximize LET’s innovative technologies as stand-alone solutions or use the Advanced Integrated Lagoon Technologies (AILT) approach to design and create the best process with technologies integrated as components that successfully meet every challenge from influent to effluent.

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA