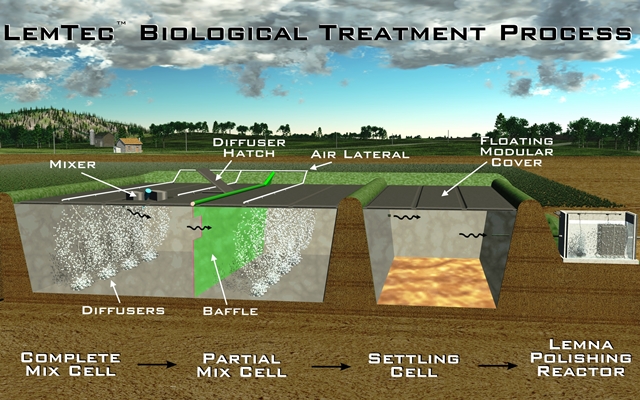

Depending on our customers’ individual, final treatment objectives, LET is able to include additional treatment steps immediately following the custom-designed LemTec™ Biological Treatment Process (LBTP) settling zone.

The need to reduce ammonia, for instance, is quite common. The use of the Lemna Polishing Reactor™ (LPR) immediately downstream of the settling zone is used to achieve ammonia limits down to less than 1 mg/l. The LPR is a submerged, fixed film, attached-growth process that creates an environment conducive to the growth of nitrifying bacteria necessary for ammonia removal and BOD polishing. Further nutrient removal, beyond ammonia may be required.

The LemTec™ Phosphorus Removal System (LPRS) can be designed into our LBTP process prior to the wastewater reaching the final LPR step. The LPRS is comprised of a chemical dosing system, low horsepower pumps and mixers. The phosphorus removal process precipitates phosphorus and allows contaminants to be dissolved or suspended to settle out as floc particles, achieving effluent of 1 total phosphorus for our clients.

Other steps can be added to adapt the LBTP and enhance its capabilities to accomplish virtually any treatment objective including Total Nitrogen (TN) removal, additional solids capture, and more. With each customized LBTP design, we are able to successfully deliver wastewater treatment solutions that meet every challenge from influent to effluent.

Learn more about Glasgow Wastewater Treatment Plant – Glasgow, MT

Learn more about Glasgow Wastewater Treatment Plant – Glasgow, MT