Ammonia-nitrogen (NH3) is converted to nitrate-nitrogen (NO3) by an aerobic biological process called nitrification. In the LemTec™ process, nitrification occurs in the Complete Mix cell of the aerated lagoon and in the Lemna Polishing Reactor (LPR). The complete mix zone of the LemTec™ Biological Treatment Process (LBTP) is an aerated, aggressively mixed cell that establishes an environment suitable for the rapid removal of BOD5 by heterotrophic bacteria. In addition to BOD5 removal, ammonia is also removed by heterotrophic bacteria present in the complete mix cell. Ammonia is utilized by the bacteria to support its nitrogen requirement for growth. Also, nitrifier growth will occur in the complete mix cell resulting in additional (and significant) ammonia reduction.

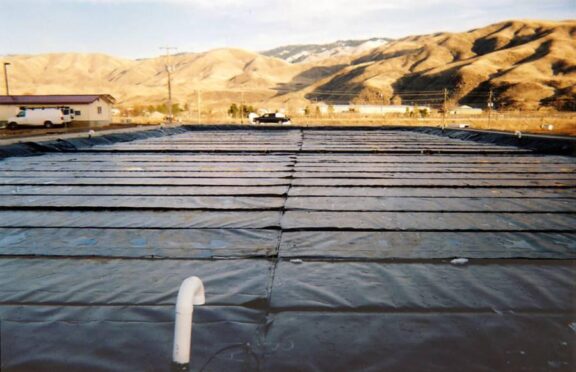

In the LemTec™ process, nitrification primarily occurs in the LPR. The LPR consists of submerged, attached-growth media modules, used for maintaining an adequate population of bacteria. Each module is comprised of plastic cross-flow media contained in a stainless steel support structure. Aeration is provided by rack-mounted coarse-bubble diffusers located under the media, which evenly distribute the air and shear coarse-bubbles into very fine bubbles.

This simple yet effective technology is ideal for supplemental BOD and ammonia-nitrogen (NH3-N) polishing. Using well proven attached-growth media technology, the LPR enhances the growth of nitrification bacteria to encourage conversion of ammonia to nitrates and nitrites in a highly aerobic environment.

Expertise as a leader in this industry for 30+ years, an arsenal of cutting-edge technologies and a groundbreaking approach set LET apart by delivering optimized solutions for wastewater applications including Nitrification to meet clients’ objectives efficiently and cost-effectively. We maximize LET’s innovative technologies as stand-alone solutions or use the Advanced Integrated Lagoon Technologies (AILT) approach to design and create the best process with technologies integrated as components that successfully meet every challenge from influent to effluent.

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA

Learn more about Kiron Wastewater Treatment Plant – Kiron, IA